Common problem of "normal quality fast connector"

1: High failure rate : the rate of one time success is not high, the insertion loss is large,

and the fiber matching Gel is easy to lost.

2:Short lifetime: the product don't work well after few days

3:With incomplete statistics, various types of faults are as high as 10%.

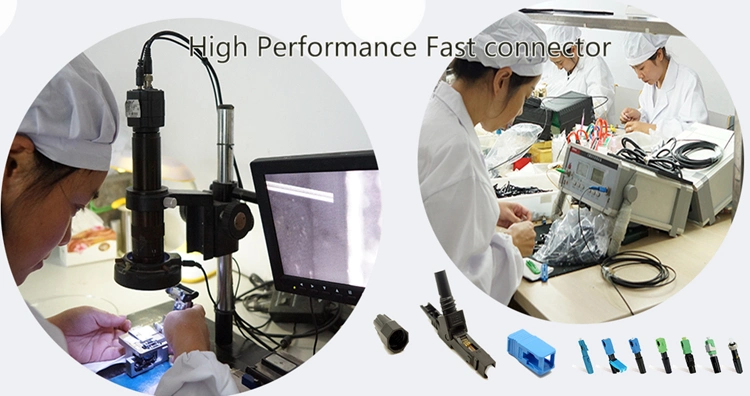

C:Our Non_Fused connector system effectively solves the problem Aboved

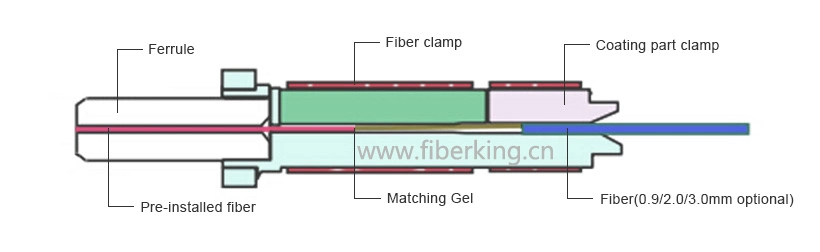

1: Ferrule is the most important component of Fiber Connectors

We use good quality Ceramic Ferrule

2: We Use high quality Special optical grease in stead of norma quality Maching Gel

The laboratory shows that the average loss time is >25 years,

and the physical docking requirements of the fiber can be well maintained during the lifetime.

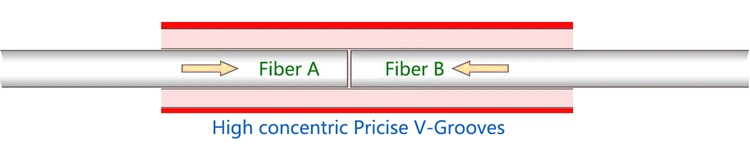

3: Precise V-Grooves and high concentric level to guarantee the low insert loss and high return loss

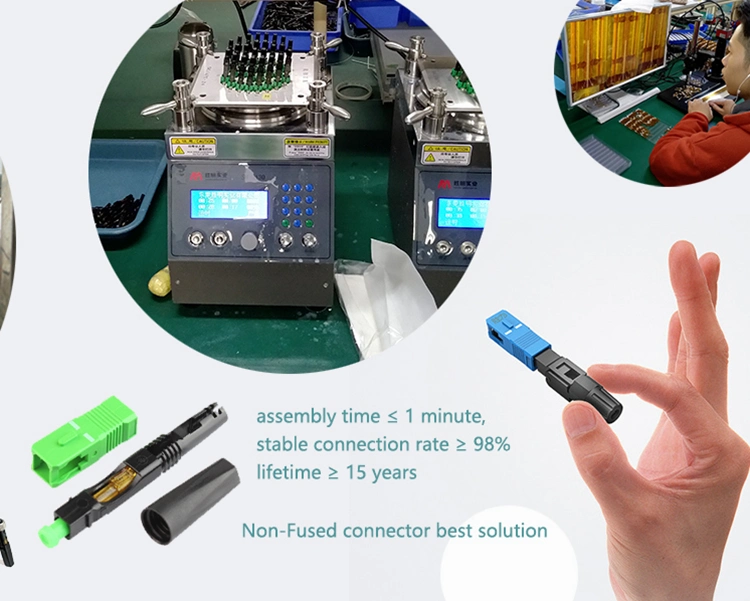

4: assembly time ≤ 1 minute, stable connection rate can reach 98% or more

5: 5 years failty rate can be as low as 2%, working life is more than 15 years

Specifications

Applicable for | 3.1x2.0mm drop cable or 3.0/2.0 cable |

Optical fiber diameter | φ125um (657A&657B) |

Tight buffer diameter | φ250um |

Fiber mode | Single mode |

Operation time | About 10s (exclude fiber cut) |

Insert loss | ≤0.3dB (1310nm & 1550nm) |

Return loss | ≥40dB |

Fastening strength of naked fiber | >4N |

Tight clamping force cladding | >8N |

Tensile strength | >50N |

Using temperature | -45ºC~+80ºC |

More design